This advanced technology is based on the principle of scraping film under a high vacuum and at high temperature.

Under these conditions, the difference between the boiling temperatures of the various molecules making up the product will allow them to be distilled, separated, concentrated or selectively fractionated.

These particular conditions always preserve the distilled product without altering the integrity of its molecules.

The treated matrices are products with high molecular weight or high viscosity; they can be oils, fats or waxes of vegetable or animal origin. Or synthetic oils or specialty chemicals or waxes.

The industrial unit consists of a Short Path Evaporator (SPE) and a Wipe Film Evaporator (WFE).

The capacity of the four industrial tanks (including two food tanks) is 15m3 per tank. Distillation campaigns can start from 1 tonne up to 13 tonnes. Larger quantities are possible but will constitute several separate lots.

Our plant operates continuously, which allows us to process large volumes in a short period of time.

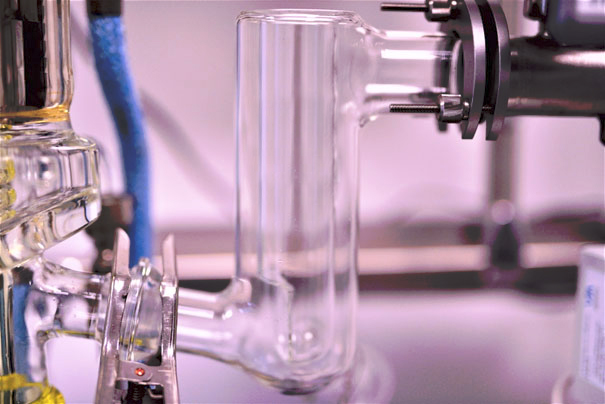

Stella has also invested in a laboratory molecular distillation unit to :

- Carry out feasibility tests (quality, yield, behaviour…)

- Determine the parameters of the industrial process to meet our customers’ objectives

- Develop new processes or distil new products

- Optimise control and improve existing processes

- Carry out small-scale continuous production

This versatile equipment allows us to distil, completely eliminate or greatly reduce the heavy compounds or molecules present in our customers’ oils, fats, waxes or speciality chemicals.